Delta’s DPX -80 series comprises Pultruded FRP Induced Draft Cross flow cooling towers. These high-strength field erected Cooling Towers have excellent corrosion properties. Made from FRP pultruded sections and FRP sheets, the series DPX-80 is the best choice for large capacity cooling towers with unclean water. In addition to strength and performance, they are environmentally safe and aesthetically pleasing.

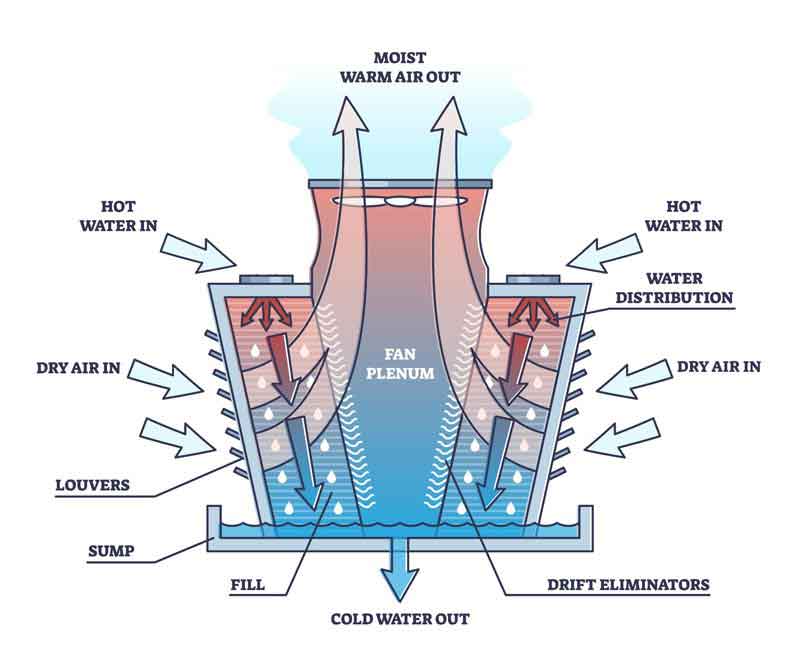

Series DPX 80 employs the cross flow principle of operation. The name "cross flow" refers to the way

the air flows across the fill media. Fan mounted at the top of the tower, pulls the air across the V-splash bar and over heated water which falls over successive layers of horizontal splash bars,

continuously breaking into smaller droplets, while also wetting the fill surface. Splash bars are available in extruded PVC material. The series provides a reliable and efficient cooling solution for industrial and HVACR applications where strength, performance and efficiency are essential.

Structural components of the tower are made up of tough Pultruded FRP sections. They can withstand exposure to saltwater, chemicals, and UV radiation. They are also resistant to bacteria and other microorganisms, making them ideal for use in many industrial applications. These towers are suitable for polluted water with very high TSS (Total suspended Solids) which cannot be met by film fill towers and for Oil and grease conc of max 500 ppm.

Casing is made of tough corrugated FRP sheets developed through hand lay-up process. These wall panels are light in weight and enhance the architectural appearance of the cooling tower. The roof deck has a non-skid surface and is able to withstand the weight of chain pulley or dolly’s wheels carrying a motor or gear box.

GRP or SS grids are used to support V bars in the cooling towers. The design offers reduced pressure drop, non-fouling ability and maximum strength.

The distribution system consists of a header with flow control valves. The hot water is collected in the top distribution basin, whereby it flows down onto the V bars by gravity. The design pattern fully distributes the water across the V bar surface even with the reduced flow rate. Spiral target nozzles made of polypropylene (non-corrosive) provide a large free passage for water on to the fill area. These can be installed or replaced very easily.

Drift eliminators are used to reduce carryover from the cooling tower. Special design drift eliminators dramatically reduces drift losses while offering a low resistance to air. They are made from preformed PVC sheets.

Inlet Louvers are made of FRP flat sections which are placed in a slanting way to prevent entry of debris and rain in the cooling tower basin and also to prevent circulating water from splashing out of the cooling water, thereby saving the costs in water treatment chemical and water. They are completely resistant to rot, corrosion or chemical attacks.

The mechanical system consists of axial type FRP fan blade with adjustable pitch connected to a speed reducer gear box with minimum service factor of 2.0. The gear box is coupled to motor through a non-overloading fully floating drive shaft with flexible steel couplings on both ends. The drive shaft is available in composite material or hot dip galvanised mild steel.

The horizontal foot mounted motor is kept out of the air steam. The motors are totally enclosed fan cooled type, IE2/IE3 efficiency with IP-55 protection and Class F insulation. Other options are also available on additional price.